Manual gearbox service is essential for ensuring smooth gear operation and extending transmission life․ Regular checks and fluid changes prevent wear, while inspections of the clutch and gear shifting ensure optimal performance․ Neglecting service can lead to costly repairs․

1․1 Importance of Regular Servicing

Regular servicing of a manual gearbox is crucial to maintain its performance and longevity․ Over time, transmission fluid degrades, losing its lubricating properties, which can lead to increased wear on gears and bearings․ Neglecting routine checks can result in costly repairs, as small issues may escalate into major problems․ Monitoring gear shifting performance helps identify early signs of wear or misalignment, while inspecting the clutch system ensures proper engagement and prevents premature failure․ Additionally, maintaining the correct fluid levels and quality is vital for smooth operation and preventing overheating․ Regular servicing not only enhances driving comfort but also reduces the risk of unexpected breakdowns․ By addressing potential issues early, drivers can extend the lifespan of their gearbox and avoid expensive overhauls; Consistent maintenance ensures optimal functionality, making it a cornerstone of responsible vehicle ownership․

1․2 Overview of Manual Gearbox Components

A manual gearbox consists of several key components working together to provide smooth gear transitions․ The main shaft and counter shaft house the gears, which are engaged by the synchromesh mechanism to synchronize speed during shifts․ The clutch, operated by the driver, temporarily disconnects the engine from the transmission, allowing for seamless gear changes․ Bearings and seals ensure proper lubrication and prevent fluid leakage․ Gear oil, typically 75w90, lubricates internal parts, reducing friction and wear․ The gearshift assembly connects to the selector fork, which engages the desired gear․ Regular inspection of these components is vital for maintaining efficiency and preventing failure․ Understanding each part’s role helps in identifying potential issues early, ensuring the gearbox operates smoothly and reliably over time․ Proper maintenance of these components is essential for extending the lifespan of the manual transmission system․

Maintenance Tasks for Manual Gearboxes

Regular maintenance is crucial for manual gearboxes․ This includes checking and replacing transmission fluid, inspecting the clutch system, and monitoring gear shifting performance to ensure smooth operation and prevent premature wear and tear․

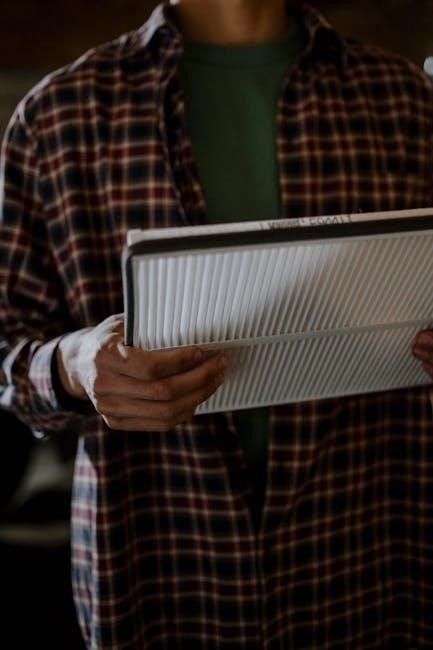

2․1 Checking and Replacing Transmission Fluid

Checking and replacing transmission fluid is a vital part of manual gearbox maintenance․ The fluid lubricates gears and bearings, preventing overheating and wear․ Typically, manufacturers recommend changing the fluid every 30,000 to 50,000 miles, though this may vary depending on driving conditions․ Signs that the fluid needs changing include darkening in color, a burnt smell, or gear slippage․ To check the fluid level, locate the filler plug usually found on the side or top of the gearbox․ Use a drain pan to collect the old fluid when draining, then refill with the specified type, often 75W-90 gear oil․ Proper fluid levels ensure smooth shifting and long gearbox life․ Regular fluid maintenance helps prevent costly repairs and keeps the transmission running efficiently․

2․2 Inspecting the Clutch System

Inspecting the clutch system is crucial for maintaining smooth operation and preventing premature wear․ The clutch connects and disconnects power from the engine to the gearbox, making it essential for proper gear shifting․ Over time, the clutch plate and release bearing can wear out, leading to issues like slippage or failure to engage gears․ Signs of wear include a spongy clutch pedal, unusual noises during shifting, or difficulty disengaging gears․ During inspection, check the clutch plate for excessive wear or warping and ensure the release bearing operates smoothly․ Additionally, inspect the clutch master and slave cylinders for leaks or damage, as these can affect clutch performance․ If any components show significant wear, they should be replaced promptly to avoid further damage․ Regular clutch inspections help maintain efficient power transfer and prevent costly repairs down the line․

2․3 Monitoring Gear Shifting Performance

Monitoring gear shifting performance is vital for identifying potential issues early and ensuring smooth operation․ Pay attention to how gears engage and disengage, as rough or delayed shifting can indicate problems․ Signs of trouble include difficulty engaging gears, grinding noises during shifts, or a “slipping” sensation where the car doesn’t accelerate as expected․ These issues can stem from worn synchros, low transmission fluid levels, or misaligned gear components․ Regularly checking the gearshift mechanism and linkage for wear or looseness is also important․ If unusual behavior persists, it may signal the need for professional inspection or adjustment․ Consistent monitoring helps maintain seamless gear transitions, enhances driving comfort, and prevents minor issues from escalating into major repairs․ By staying attentive to shifting performance, drivers can enjoy a more responsive and reliable manual gearbox․ Regular checks ensure optimal functionality and extend the lifespan of the transmission system․ Early detection of problems saves time and money in the long run․

2․4 Recommended Service Frequency

Regular servicing of a manual gearbox is crucial to maintain its performance and longevity․ Most manufacturers recommend servicing the gearbox every 30,000 to 60,000 miles, depending on driving conditions․ For vehicles used in heavy traffic or extreme weather, more frequent checks are advised, typically every 30,000 miles․ Transmission fluid should be changed every 30,000 to 50,000 miles, as dirty fluid can lead to premature wear․ Additionally, the clutch system and gear shifting mechanism should be inspected every 15,000 to 30,000 miles․ Adhering to these intervals ensures smooth operation and prevents costly repairs․ Factors like driving habits and environmental conditions may require adjustments to the service schedule․ Always consult the vehicle’s manual for specific recommendations․ Regular maintenance not only prolongs gearbox life but also enhances overall vehicle performance․ Neglecting these intervals can lead to severe damage, making it essential to stay proactive with servicing․ Proper care ensures reliable gear shifting and optimal drivetrain efficiency over time․

Repair and Rebuilding of Manual Gearboxes

Manual gearbox repair involves diagnosing issues like worn bearings or synchros, followed by disassembly, inspection, and replacement of faulty components․ Rebuilding ensures optimal performance and extends gearbox life, often costing less than replacement․

3․1 Common Issues in Manual Transmissions

Manual transmissions often face issues like worn bearings, damaged synchronizers, and clutch wear․ Bearings may fail due to excessive heat or load, leading to grinding noises․ Synchronizers can wear out from frequent gear grinding, causing difficulty in shifting․ Clutch problems arise from overheating or misuse, resulting in slippage or failure․ Leaks from the transmission case or seals can lead to oil loss, damaging internal components․ Noisy operation, such as whining or clunking, may indicate worn gears or shafts․ Drivers may also experience issues like stuck gears or excessive play in the shifter, often due to linkage wear․ Regular servicing helps identify these problems early, preventing costly repairs; Addressing these issues promptly ensures smooth operation and extends the gearbox’s lifespan․

3․2 The Rebuild Process

A manual gearbox rebuild involves disassembling the unit to inspect and replace worn or damaged components․ The process begins with removing the gearbox from the vehicle and stripping it down to its core components․ Bearings, gears, and seals are carefully examined and replaced if necessary․ The clutch system is also inspected, and any worn parts, such as the clutch disc or pressure plate, are renewed․ Once all components are cleaned and lubricated, the gearbox is reassembled, ensuring all tolerances and torque specifications are met․ Finally, the system is tested to confirm smooth operation and proper gear engagement․ This thorough process restores the gearbox to optimal performance, addressing any underlying issues and preventing future breakdowns․ Regular rebuilds are essential for maintaining reliability, especially in high-mileage vehicles․

3․3 Specialists vs․ DIY Repairs

When it comes to manual gearbox repairs, deciding between hiring a specialist and attempting a DIY fix is crucial․ Specialists offer extensive experience and tools, ensuring precise and efficient repairs․ They handle complex issues like gear alignment and bearing replacement, often with warranties․ DIY repairs, while cost-effective, require mechanical aptitude and time․ Without expertise, mistakes can lead to further damage or safety risks․ For minor tasks like fluid changes, DIY is feasible, but major overhauls are best left to professionals․ Balancing cost, time, and skill level helps determine the best approach for maintaining gearbox reliability and performance․

3․4 Cost Considerations

Manual gearbox service costs vary based on the type and extent of work required․ Routine maintenance, such as fluid changes, is relatively inexpensive, typically ranging from $50 to $200․ Inspecting and replacing clutch components can cost between $300 and $1,000, depending on the vehicle and labor rates․ Major repairs, like bearing or gear replacements, can escalate costs to $1,500 or more․ A full rebuild might exceed $2,500, especially for high-performance or specialized gearboxes․ DIY repairs can save on labor costs but require purchasing tools and parts, which may still add up․ Preventative maintenance, such as regular fluid checks, helps avoid costly overhauls by identifying issues early․ Balancing immediate repair expenses with long-term savings is key to managing manual gearbox service costs effectively․